- What the F*** is Fashion-Tech

- Posts

- From Chatbots to Chatters — Why Autonomous Knitting Machines are an Underrated Frontier of Fashion Intelligence

From Chatbots to Chatters — Why Autonomous Knitting Machines are an Underrated Frontier of Fashion Intelligence

The Financial Times recently wrote on the surge of AI agents and chatbots integrating into e-commerce. While consumer-facing AI grabs all of the headlines, the real heroes shaping tomorrow quietly hum in the background: enter autonomous knitting machines. Let’s unravel this overlooked gem.

In the last newsletter, we covered Robotic Sewing Machines, and how they’re overcoming a challenged path to commercial use. This week, let’s look into knitters. But first, what’s the difference between the two? Sewers generally handle woven fabrics, while knitters can create a whole garment with one piece of yarn (string). Yes, you heard that right. Here are a few initiatives working on autonomous knitting machines, i.e., machines that take one piece of yarn and a body scan, and spit out a whole customised garment without human intervention.

The Current Landscape of Whole Garment Self-Knitters

I. Scan-to-Stitch Precision: SHIMA SEIKI’s WHOLEGARMENT® flat-knitters pair with the SDS-ONE APEX4 “Virtual Fit” design platform to turn a 3-D body scan into a single-pass, seam-free garment—no grading, linking, or sewing required.

Additional Resources: WHOLEGARMENT overview, SDS-ONE APEX4 design system

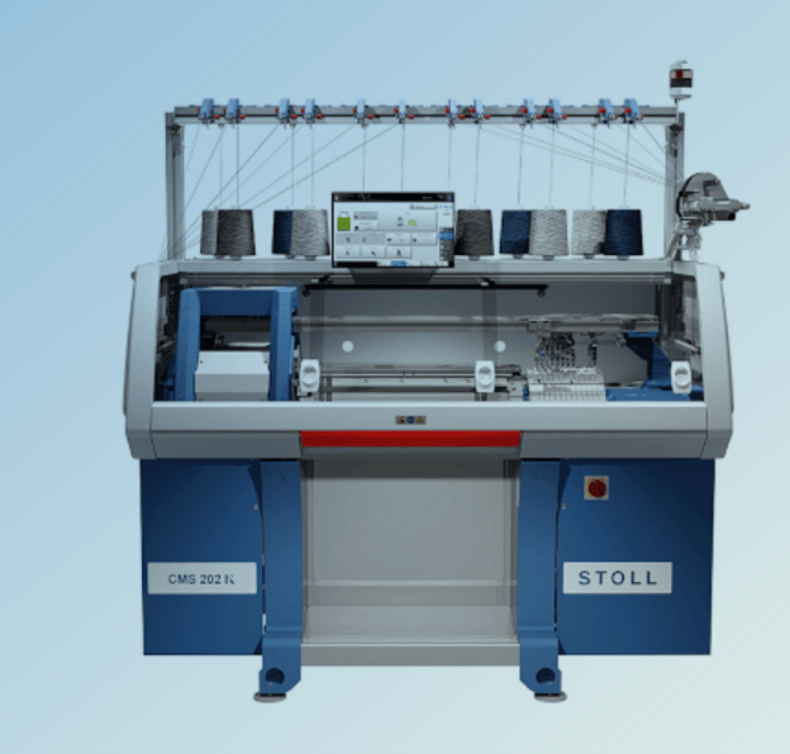

II. Legacy Meets Automation: STOLL’s autocreate® flat-knitting seamlessly integrates automation from digital design to finished fabric, eradicating manual pattern and sizing adjustments. Used in Adidas’ 2022 ‘Knit for You’ Project.

Additional Resources: Stoll Knit and Wear, Stoll flat knitting machines produce ready-to-wear 3D flat knits

III. Warp-Speed Woven Autonomy: UNSPUN’s VEGA™ 3-D weaving loom, doesn’t knit, yet ingests an iPhone LiDAR scan and weaves a custom-fit jean “tube” in under 10 minutes, enabling local micro-factories and near-zero inventory.

Additional Resources: Meet VEGA™, Vogue Business – Unspun’s 3-D woven pants

Yes, these initiatives seem far from home, but not to worry. One Australian university has made considerable investment to be ahead of the curve.

Autonomous-Machines Living Around Us

UTS's Seamless Leap: UTS introduced the Southern Hemisphere’s first Shima Seiki WHOLEGARMENT machine, crafting seamless, zero-waste knitwear—revolutionising local textile innovation and education.

Additional Resources: Knit one, purl 1000: meet the Shima Seiki knitting machine

Go us. It’s about time our education and access to cutting-edge tech fell above the curve. While this is a great start, we need to see more connectivity between these resources and industry. Meaningful collaboration to on-shore independent manufacturing means efficiency and an economic boost. Fashion is the last trillion-dollar industry to automate, and what good are resources sitting in a university lab instead of adding to our economy. Collectively we need to overcome the industries inertia to change, piece together our fragmented supply-chains and innovate a way forward; sharing overheads and running leaner businesses as a collective hub. This is our future as a country and as an industry of decentralised small businesses. UTS is constantly looking for industry partners to use this machine, and it’s up to industries early adopters to take the leap.

So where to from here and why is now the right time to move?

Geo-Politics & Sustainability

Tariff Tensions: Recent U.S. tariffs (10–50%) on international textile imports have brands scrambling to near-shore operations, seeking reliability amidst ongoing trade-war volatility (Vogue Business). Autonomous knitting in our back yard provides precisely the resilience needed. Commercialising these resources help all near-by small brands, run with the same efficiency as the conglomerates.

Regulatory Push for Transparency: Increasingly stringent EU, U.S. (maybe), and Australian regulations on carbon disclosures put on-shoring manufacturing as a potential solution. This puts automated knitting in the spotlight due to its inherent sustainability advantages, significantly reducing fabric waste and carbon footprint (Fashion Law Journal).

Win-Win for Brands: Efficiency Meets Sustainability

Eco-Friendly Footprint: 3D knitting slashes fabric waste by up to 30% and energy usage by 40% compared to traditional manufacturing (threadden.com).

Cost & Time Savings: On-demand local production dramatically cuts shipping and labor costs, responding to market demands in hours instead of weeks.

Personalisation at Scale: Quick digital-to-fabric capabilities allow brands to effortlessly customise designs and sizing, meeting diverse consumer needs without excess inventory.

Smart Knitting is Connected Knitting

IoT Integration: Real-time monitoring and cloud-connected pattern libraries streamline global team collaboration, troubleshooting, and production.

Seamless Systems: Integration with ERP and PLM platforms enables smooth scaling, accurate tracking, and ultimate production transparency.

In summary, business is tough and innovation is imperative. Let’s collaborate and commercialise these assets! A more connected industry is a more efficient and successful one. Humans didn’t beat the lions with larger teeth, they collaborated. Let’s put our brains together, this time not for world domination, but for salvation.

Pop-Feature

UTS Centre of Excellence in Sustainable Fashion & Textiles

What they do

The University of Technology Sydney is home to the Southern Hemisphere’s first Shima Seiki WHOLEGARMENT seamless knitting machine. This machine knits fully-fashioned garments in one piece, eliminating fabric waste and removing the need for traditional cut-and-sew operations. Through this and their broader research, UTS is pioneering Australia's push into sustainable, automated, and on-shore textile manufacturing.

Why it matters

This is not just a machine drop. UTS is embedding automation and circularity into the education system, training the next generation of designers and textile engineers in real-world applications of fashion tech. It’s a blueprint for how institutions can drive meaningful change at scale, bridging innovation and industry.

Impact scorecard

We rate UTS an 7/10. They’re not just talking about the future of fashion, they’re building it—with hardware, talent, & vision. Autonomous machines have one huge down-fall — up-front investment and skilled labour to manage the machines. They’ve tackled both in one hit, and are playing the long game by embedding sustainability and automation into the curriculum. Still, academic outputs can be slow to scale commercially—we're excited to see partnerships blossom and tech move from campus to factory floor.

That wraps up this edition of ‘What the F*** is Fashion-Tech’. If you have any thoughts or we got something wrong, please respond to this email. We love to chat.

We’ll see you in two weeks. Take care of yourself and don’t forget to tell your friends about us.

Thanks,

Grace & Rak