- What the F*** is Fashion-Tech

- Posts

- The Valentino Handbag Scandal Spread Around Milan

The Valentino Handbag Scandal Spread Around Milan

“Made in Italy” isn’t quite the fairytale that we imagined. Last fortnight, a Milan judge put Valentino Bags Lab under judicial administration for subcontracting to sweatshops where staff were sleeping next to sewing machines. Italy may spin ~50 % of the world’s luxury goods, but opacity can stitch abuse into every seam. Let’s unravel the mess…and the tech fighting back.

AI - Generated

Valentino’s Very Public Time-Out

Milan judges just put Valentino Bags Lab under a one-year “corporate babysitter”, formal judicial administration, after officers found undocumented migrants working marathon, 24-hour shifts in subcontractor lofts where safety guards were literally ripped off sewing machines. The worst part? Bags that retail for A$3k were sewn for as little as €75 a pop. [Sources: WSJ, NDTV]

Déjà vu in designer land. Valentino is the fourth luxury label benched since 2023:

Alviero Martini (Jan 2024)

Giorgio Armani Operations (Apr 2024)

Dior’s leather arm (mid-2024)

Valentino Bags Lab (May 2025)

Each got the same court-order for lack of visability, or worse, turning an eye to sweatshop labour.

Why does this matter? Italy still churns out over half of the world’s luxury goods— I know, I was surprised too. So when Milan sneezes, global lead times catch a cold and handbag margins suffer. [Source: Reuters]

The industry’s “fix-it-or-forget-it” pact — Stung by the headlines; courts, unions, & brands signed a 26 May 2025 accord to build a voluntary supplier database. Signing on equals a shiny Certificate of Transparency for brands; while avoiding it risks being the next courtroom target.

The luxury world’s favourite outsourcing game just ran out of free admissions. If your favourite label can’t trace every stitch, Milan’s judges will force them to for you.

Meet the Traceability Avengers

TrusTrace

A 13 May 2025 AI upgrade compiles supplier docs, scans them against the US CBP forced-labour list and 200+ other risk databases in seconds.

55,000+ factories and >2 million POs already mapped; Adidas and Primark use it for blockchain-secure material passports.

Why it matters: Real-time red flags mean a brand can freeze a shady subcontractor before fabric hits the cutting room—exactly the blind spot that tripped Valentino.

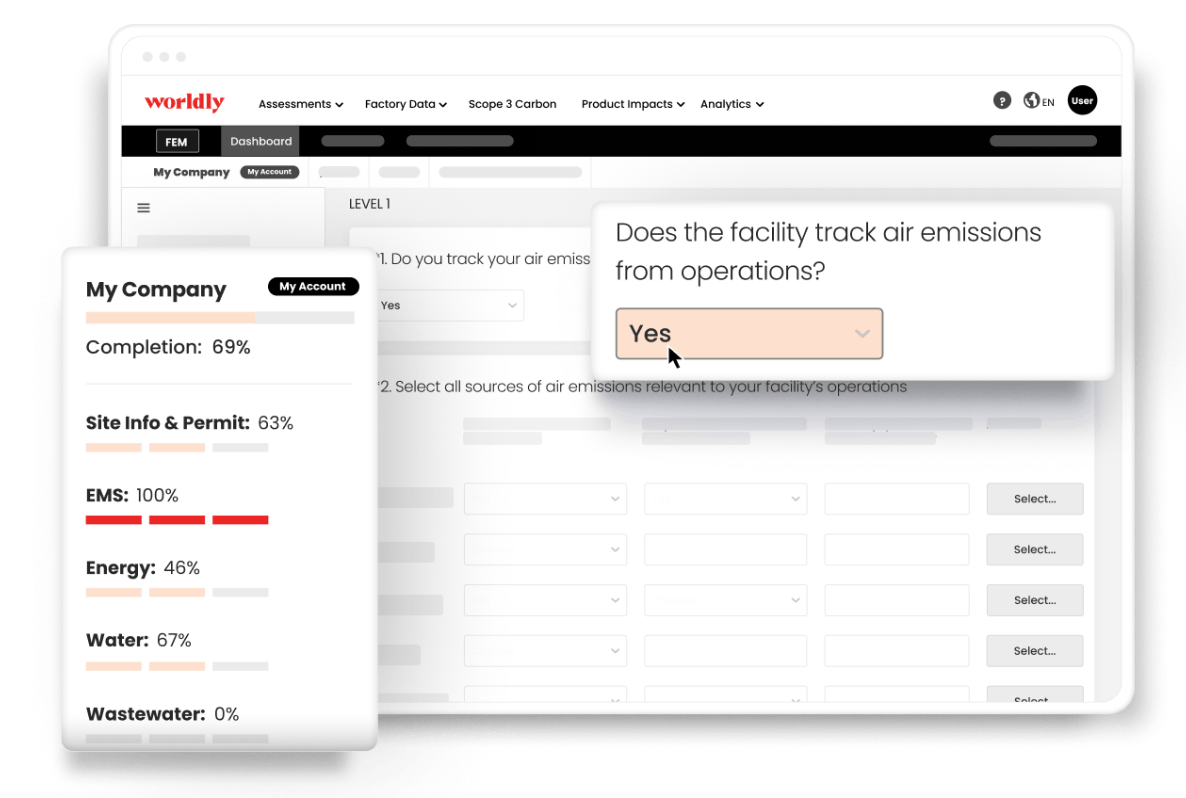

Worldly

Worldy’s Insights Hub turns raw factory uploads into a dashboard of the Top-5 decarbonisation KPIs—energy mix, Scope 3 emissions, water, waste and labour scores—launched 13 May 2025.

350+ brands & 40,000 factories feed live data — H&M uses it to pre-calculate France’s 16-indicator Eco-Score for every SKU.

ANZ angle: Aussie labels eyeing EU shelves can go directly through Worldly and skip hiring an LCA consultant (which is also cheaper than PR damage control).

Glimpact

Free Global Impact Score tool (8 May 2025) crunches the EU-approved 16-category PEF model, then shows impact changes live when you swap fibres or factories.

In a 100-product study, Glimpact found 90 % of a garment’s footprint piles up before sewing—so fabric choice dwarfs plastic-bag debates.

Why it matters: Perfect sandbox for designers—tweak, re-tweak, and land an EU-ready eco-score without a single spreadsheet meltdown.

ANZ is Catching-Up

Over 12,500 mandatory modern-slavery statements covering 22,600+ entities now sit on Canberra’s public register, and penalties for slack reporters are on the way

[Source: modernslaveryregister.gov.au]

Smart local moves:

Map supply chains beyond Tier 1 before EU’s forced-labour ban (Reg 2024/3015) hits in 2027.

Plug traceability data straight into AU Modern-Slavery dashboards, regulators love primary data receipts.

Geo-politics & Sustainability

The EU’s new ban enables customs to withhold goods with dodgy labour links (deemed by traceability tech); Italy’s courts are currently the guinea pig. Meanwhile, Canberra is teasing a ‘due-diligence duty’, not just disclosure. Expect insurers to price in supply-chain opacity and CFOs to ask for traceability ROI, fast.

What This Means for Brands

Traceability tech flips the narrative from “we didn’t know” to “prove you care”. It holds brands accountable, finally.

Upside: de-risk accessing the EU market, lower audit costs, and marketing gold (QR codes shoppers want to scan).

Risk: invest late and watch competitors win procurement deals with data-rich moves.

Provocative Q: Would you still tap Buy Now on that must-have jacket if you knew its backstory before it left the factory floor?

Pop-Feature:

FibreTrace

What they do: Embed microscopic, luminescent pigments into cotton, wool and even recycled polyester; every scan writes a tamper-proof record to the cloud—no extra labelling, no blockchain bottleneck. Meaning human eyes aren’t accountable here, the cotton tells the story - and it won’t lie.

Why it matters: Physical + digital twin means zero room for “mystery cotton”—perfect for EU Digital Product Passports.

Impact scorecard: 8/10. It’s hacker-proof, fibre-level fingerprints keep mystery cotton out of the picture, it dishes up real-time carbon and water receipts, and it turns Aussie farms and factory floors into a local hero.

The only drawback? Those luminous threads still clock in a touch pricier per metre than average cotton… but once volume kicks in, it should iron itself out.

Check them out here.

So, that’s the tea. Forward to a friend who still thinks “Made in Italy” guarantees quality (we all know one), or hit reply and tell me what traceability details you would want to see while shopping.

We’ll see you in two-weeks time. Take care of yourself & don’t forget to subscribe.

Grace & Rak