- What the F*** is Fashion-Tech

- Posts

- VivaTech 2025: Where Silicon Valley Meets Parisian Couture

VivaTech 2025: Where Silicon Valley Meets Parisian Couture

Unless you’ve been hiding under a rock (or a pile of unsold Shein stock in this context), you’ll know the tech world has just wrapped up its annual pilgrimage to Paris for VivaTech 2025. If you thought fashion week was chaotic, imagine 180,000 tech heads, luxury execs, and robots descending on the City of Lights to decide the future of, well, everything fashion. If you haven’t heard of it, this is VivaTech.

What Is VivaTech (And Why Should You Care)?

Born in 2016, when Maurice Lévy (Chairman, Publicis Group) and tech publisher Les Echos decided Paris needed its own luxury coded answer to CES (the most powerful tech event in the world); VivaTech has evolved from a cute startup showcase, into one of Europe's largest tech event. This year's edition broke every record: 180,000 visitors, 13,500 startups, and enough robots to film the next Terminator sequel.

But here's the kicker, unlike your typical Silicon Valley circle jerk, VivaTech has luxury in its DNA. LVMH doesn't just sponsor, they actively pilot tech with startups on the show floor. When Bernard Arnault's crew starts playing with blockchain and robots, you know fashion-tech just got serious.

Key players orchestrating this tech symphony:

Publicis Groupe (the marketing giant that knows how to throw a party)

Les Echos (France's version of the Financial Times), bringing media muscle)

The French Government (enough said)

The Big Five: VivaTech 2025’s Major Innovation Themes

1. AI-Powered Everything

From generative design to customer segmentation, AI is now the backbone of every industry. NVIDIA and France’s Mistral AI dropped a sovereign cloud platform, while startups like Kahoona are using real-time AI to personalise digital experiences with Dior already on board. Even luxury brands are getting in on the action, using AI to forecast demand and keep you coming back for more. Yes, you heard that right — and this is just the beginning.

2. Robotics Revolution

Humanoid robots, warehouse bots, and AI-powered factory arms were everywhere. China’s Unitree Robotics and France’s LOGIE-AI showed off robots ready to take on everything from disaster zones to your local Zara distribution centre. Lifelike service robots like Enchanted Tools’ Mirokai and Engineered Arts’ Ameca (yes, the one with the creepy human face) had crowds both awed and slightly terrified.

3. Sustainability Tech That Scales

This year’s Impact Bridge pavilion was packed with startups fighting climate change with everything from regenerative agriculture data to carbon tracking software. LVMH’s “Best Impact” award went to Genesis, a platform using soil data to make vineyards more sustainable. Electric vehicles, hydrogen SUVs, and even solar-powered cars made mobility a climate battleground.

4. Web3 Gets Real

The crypto bros are still kicking, but now with less hype and more utility. NFTs (Non-fungible tokens) are being used for loyalty, traceability, and even biodiversity (see Guerlain’s Cryptobees). The metaverse isn’t dead, Dior’s interactive avatar universe and Perfect Corp’s AI-powered virtual fitting rooms are proof that digital twins and AR try-ons are here to stay.

5. Industrial Tech Infrastructure

Cloud, chips, quantum computing, the boring stuff that makes everything else possible. NVIDIA is building Europe’s first industrial AI cloud in Germany. Bosch, Siemens, and a wave of startups demoed IoT sensors, predictive maintenance, and blockchain-based supply chain tools. The future? Every product, factory, and delivery truck is connected and data-driven.

Let’s deep dive into our core topics: Traceability & Advanced Manufacturing

What did VivaTech 2025 mean for fashion supply chain and manufacturing?

Traceability

LVMH’s Machine Zero (with Loro Piana) uses AI to scan cashmere for impurities, tracing each fibre “from goat to garment.”

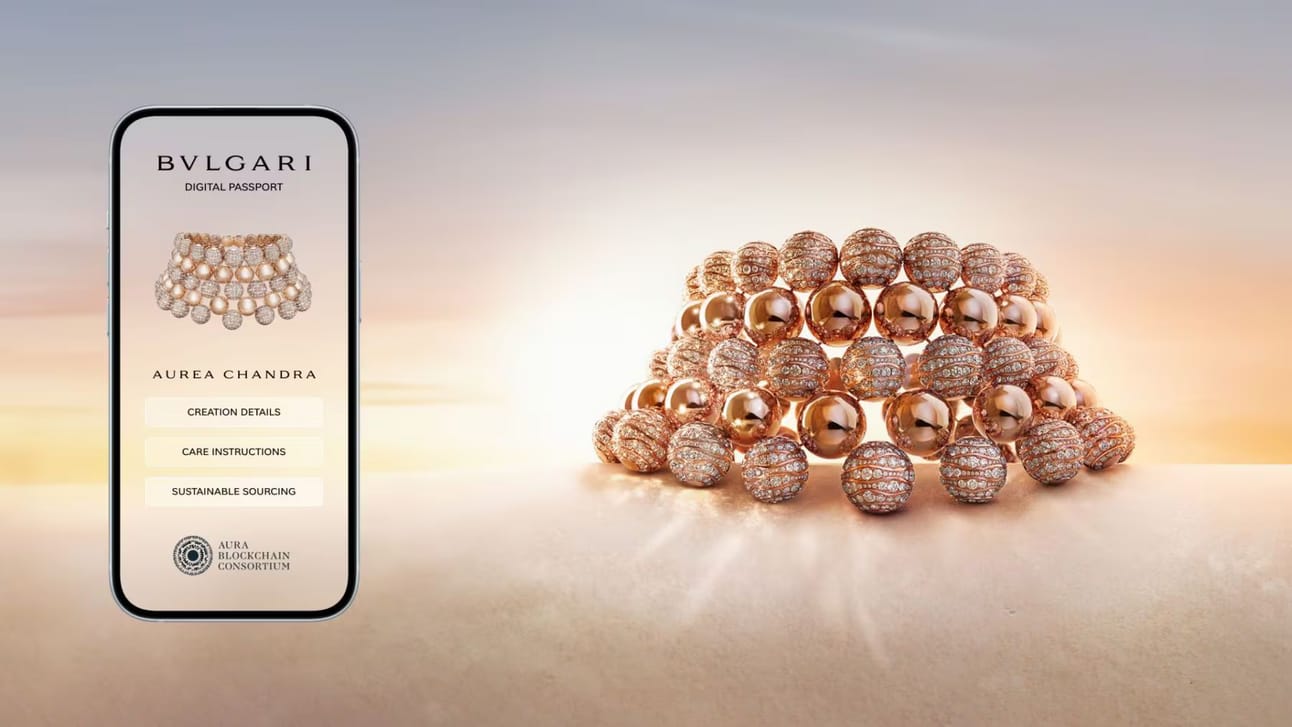

Bulgari’s Dev4Side digital passport micro-engraves serials into jewellery, scan it, and you get a full eco-resumé.

VRAI’s AI gadget can spot a fake Lacoste polo in seconds.

Damo’s digital certification platform promises supply chain trust, while Optikan’s material scanner verifies fibres on the spot.

Advanced Manufacturing

LVMH x Rigsters 3D digitisation rigs let you create a digital twin of a handbag in minutes.

OKCC’s robotic arms painted Cognac decanters with the precision of a Swiss watchmaker, imagine that tech on your next limited-edition sneaker drop.

Generative AI + 3D Printing had startups auto-generating complex geometries for everything from shoe soles to jewelry. The magic? AI designs structures that humans couldn't imagine, then prints them on demand… Innovation at it’s finest. It’s not AI replacing humans, it’s AI in collaboration with humans.

Why It Matters

Transparency is now the cost of entry: We’ve said it before and we’ll say it again, if you can’t trace your supply chain, you’re out. EU digital product passports and forced-labour bans mean brands need to show receipts, literally.

Automation isn’t optional: Robotics and AI are driving down costs, speeding up production, and enabling on-shore manufacturing. If you’re still sewing by hand, you’ve got two options — stay niche, or restructure.

Sustainability is a selling point: From biodegradable polymers to green shipping, the pressure to go eco-friendly is now global and regulatory, not just a marketing flex.

What Does This Mean for ANZ?

ANZ’s geographical remoteness no longer shackles its fashion industry:

Traceability Tech: Machine Zero, like technology could revolutionise ANZ wool producers' transparency, strengthening global market trust.

Smart Manufacturing: 3D digitisation and AI-driven prototyping could slash ANZ's sample shipping, enhancing speed-to-market.

Logistics Innovations: Solutions like OptiOryx and Appload Freight Broker could optimise ANZ’s complex logistics, reducing freight costs and environmental impact.

Pop-Feature

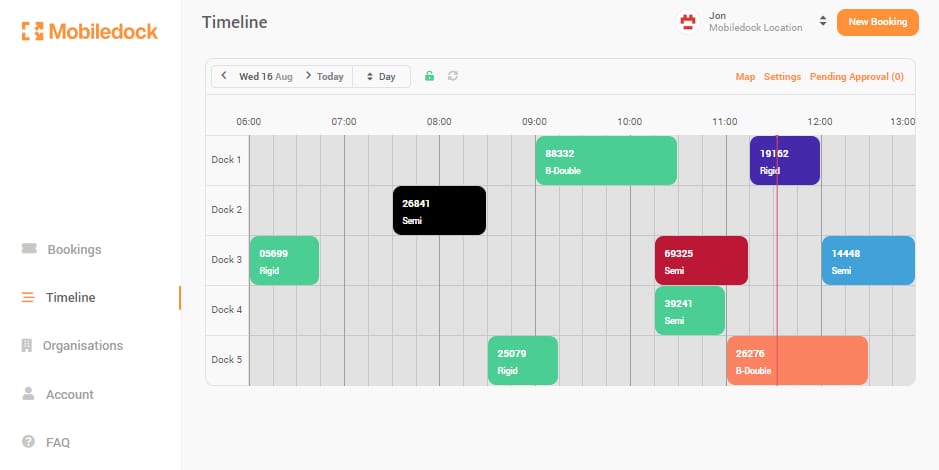

Mobiledock

What they do: This Melbourne startup turned loading docks from chaos to clockwork. Their cloud platform is "air traffic control for deliveries", carriers book slots, algorithms optimise schedules, and suddenly your distribution centre runs like a Swiss watch.

Why it matters: Fashion's seasonal inventory surges just met their match. Mobiledock users report 30% fewer loading bays needed and 40% higher throughput. For retailers, that's faster stock turnover and eliminated demurrage fees. Already deployed at Sydney's Barangaroo and Melbourne's Emporium, proving Aussie innovation can solve global problems.

Impact scorecard: 7/10. They've cracked a universal logistics headache with elegant simplicity. The platform's pick-up-and-deploy nature means any fashion distributor can implement it tomorrow. This is one of those hidden gems that never reaches the headlines, but is silently ticking away in the background making everyone else look good.

Finishing up with a provocative question, If a robot can paint a $14,000 Cognac bottle and AI can verify cashmere quality better than human experts, what exactly is "handmade luxury" in the modern era? Drop us your thoughts.

See you in two weeks. Take care of yourselves and remember, the robots are coming, but they're here to help (mostly). And forward this to your friends who loves luxury. Sayonara.

Grace & Rak